Our services

Production

Production for your unique needs

Flexibility and in-dept expertise at our own world-class facilities. Advanced prototype production, series manufacturing, and tailor-made solutions of the highest standards.

Our Global Production

Syntronic operates production sites in Kumla and Sandviken (Sweden), Ottawa (Canada), and Timișoara (Romania). Across these locations, we offer a flexible mix of electronics manufacturing services (EMS) capabilities from rapid prototyping to advanced series manufacturing tailored to customer needs. Our sites are equipped with technology and expertise to support different parts of the production lifecycle, with close integration to our global R&D teams

OEM manufacturing

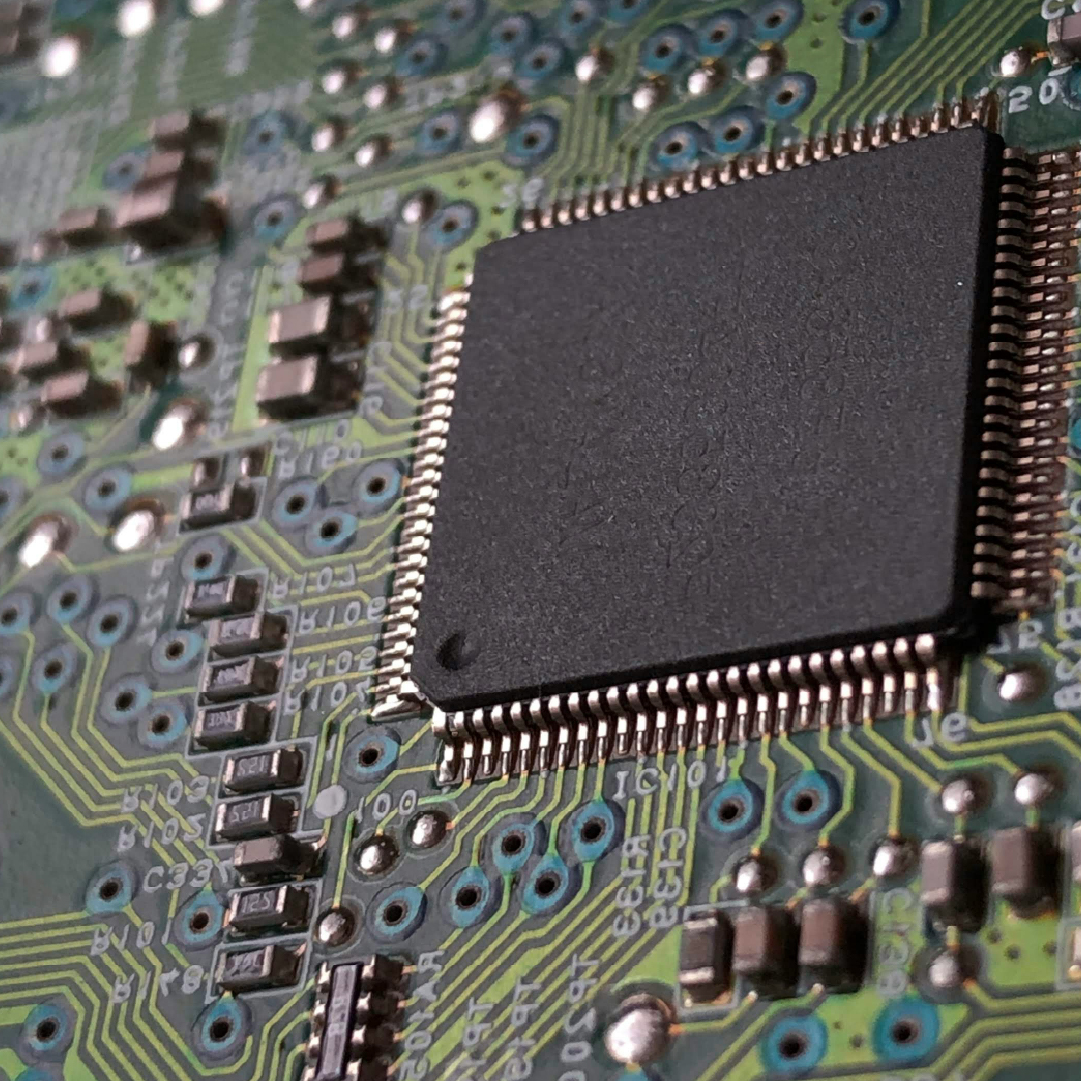

World-class production facilities

We deliver top-tier OEM production with exceptional delivery precision and uncompromising quality. We can be your electronics manufacturing services (EMS) provider/contract manufacturer (CM).

Backed by deep industry expertise, we turn your ideas into concrete, high-performing products. Experience the simplicity, flexibility, and seamless partnership that define the Syntronic way of working.

One-stop-shop

With our comprehensive one-stop-shop offering, we support your entire product journey, from early prototyping and design validation to full-scale series production. Whether you're launching a new concept or scaling an existing product, we provide the flexibility to step in wherever you need us the most. Enjoy the efficiency, reliability, and peace of mind that comes from working with a single partner who understands your vision and delivers results.

Our production sites can support with value-add services such as supply chain & life-cycle management and NPI support including DFX (DFM/DFT/DFE etc.). The proximity to our world class R&D centres can support with PCB design and layout, functional test systems and more, which makes Syntronic your true one-stop-shop solution to product design and ownership.

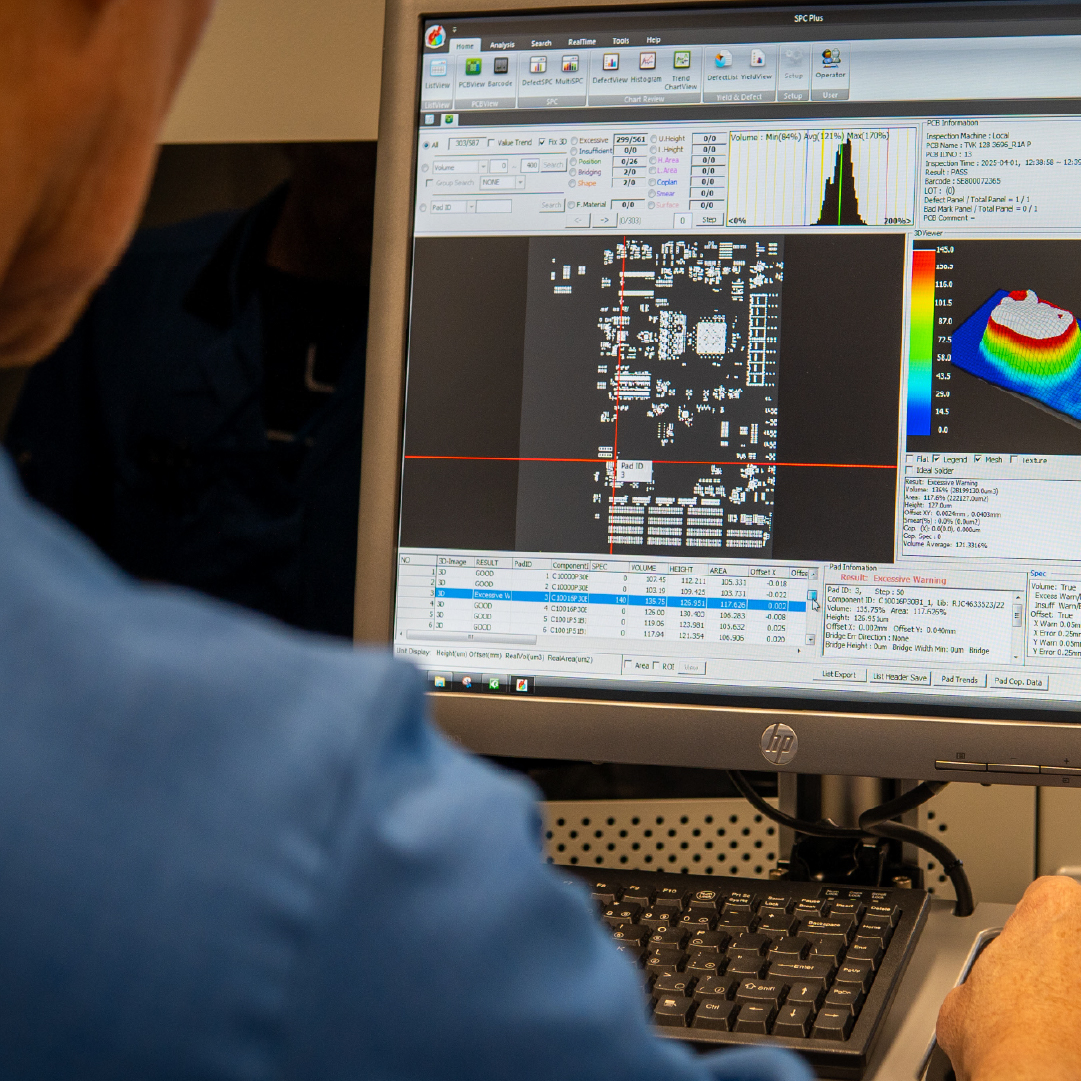

Extensive testing and analysis capabilities

Our in-house electronics analysis lab is equipped to perform a wide variety of tests to support product quality, durability, and compliance. We offer everything from climate and environmental testing to cross-sectional analysis of electronics using cold mounting in resins.

Automated optical inspection (AOI) is key in today’s electronics manufacturing and at our production sites this is complemented by many other electrical, mechanical, and visual test methods.

With flexible setups and a broad range of tools, we can tailor our testing approach to meet both industry standards and specific customer requirements across the development, production, and validation phases.

Adaptable production

We support both high-mix, low-volume and low-mix, high-volume production requirements. Our processes and systems are designed to handle frequent product changes, complex assemblies, and shorter production runs, as well as streamlined, high-volume manufacturing of standardized products. This flexibility allows us to meet diverse customer needs across different industries and project scopes.

Whether quick-turn CCA/PCBA prototyping or volume electromechanical manufacturing is what you’re looking for, together with our commitment to customer value we will support your needs!

Core competences and capabilities*

- Multiple SMT lines

- Quick turn prototyping, in as little as 3 days

- Volume capability with >200 000 placements/hour and panel sizes of >1000x600mm

- Full CCA/PCBA validation capability, including

- SPI, AOI (pre and post reflow), X-ray, flying probe, ICT

- Through-hole soldering (selective and manual)

- Cleaning and Coating of PCB and/or CCA/PCBA

- Full electromechanical integration/assembly with configuration

- Quality Management System

- Mechanical design and CNC workshop

- Cable assembly

- Project and configuration management

*Exact capabilities per site may differ.

Business models

Our business models cover time and material, fixed price, and box solutions. We welcome the opportunity to use incentive-based models and are happy to discuss new or alternative business models.

Our global service portfolio covers outsourced assignments at our premises, specialist consultants at our partners' sites, and platform-based solutions for increased efficiency and cost-effectiveness.

Related news

Grand Opening – Syntronic Production Canada

CES 2026 recap: From emerging technologies to real-world systems

Syntronic expands manufacturing operations in Ontario, Canada

One-stop-shop:

A complete journey from prototype production to series manufacturing.

Our offer

Read more about our services

Aftermarket

Benefit from our local presence while having access to our international expertise.

Get in contact with us

"*" indicates required fields